The conclusions of the third report on the Foodtech sector in Spain were presented at the ICEX Auditorium. In the framework of this event, some of the main players of the ecosystem have discussed the challenges and the internationalization strategy for this sector. The food technology sector is an essential link in the Spanish food industry.

An intense transformation of food is taking place as a result of the impact of new technologies and the foodtech ecosystem is set to play an essential role in this process in the coming years.

Thus, in a context of global contraction, investment in the foodtech sector in Spain in 2022 has increased by 9.38%, reaching 268 million euros, discounting the Glovo effect, as revealed in the report “Addressing new challenges across the food value chain” promoted by ICEX Spain Export and Investment.

But not only has it been able to attract major investment operations with national and international players, but there has also been a significant increase in the number of operators in the ecosystem: 412 startups, compared to 407 last year, more than 30,000 companies involved in food transformation, as well as more than 50 specialized universities and 20 cutting-edge technology centers involved.

These are just some of the conclusions drawn from the report on the Spanish Foodtech sector in 2022 presented, an essential link in the Spanish food industry.

This third report also points out that, in order to consolidate in the ecosystem, it is essential to have a high technological capacity and strength, which translates into patents, trade secrets and trademarks. Thus, 32.9% of the 412 Spanish startups have a patent for their technology and 29% have a trade secret, which indicates the robustness of Spanish companies in the sector.

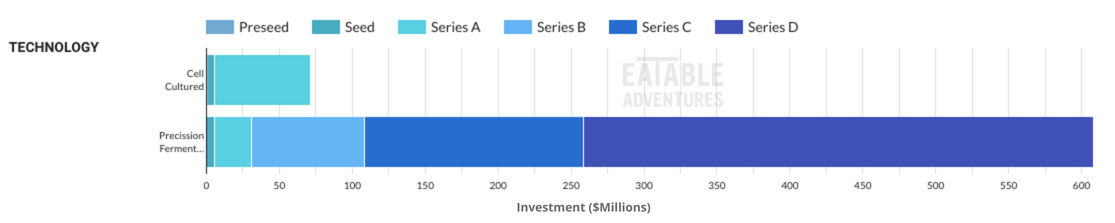

Moreover, during 2022, the percentage of startups that have developed their own technology has further increased. In this area, there is a spectacular growth in the use of technologies, mainly startups that use artificial intelligence (AI), rising from 28.21% to 40.79%, gaining 12 points over the previous year.

It is worth highlighting the sector’s contribution in terms of circular economy, providing those technologies that allow the re-valorization of by-products, thus reducing waste and creating new uses ranging from packaging to ingredients.

ICEX CEO, María Peña, opened the event to present the report, highlighting that it is “a fundamental sector for attracting capital and investment in startups”. She stressed that “it has become a key of high added value in any strategy in favor of knowledge and expansion of our ecosystem of innovative and technological entrepreneurs” and also noted “the sector’s commitment to sustainability and making this attribute its flag”.

Likewise, María Peña emphasized that “there is no promotional strategy that is not based on knowledge”, and in this sense, “this report, within the framework of our alliance with Eatable Adventures, is undoubtedly a fundamental element of that knowledge”.

In closing his speech, Peña wanted to put on record that “if Spain will continue to be a Spain Food Nation, it will be so because it is also a Spain Foodtech Nation”.

To download the report, click here